FACILITATED SIDE UNLOADING

The floor of the three-way tipper and the sideboard positioned at 90° superimpose perfectly with no space between them. Side unloading is accurate and clean.

The floor of the three-way tipper and the sideboard positioned at 90° superimpose perfectly with no space between them. Side unloading is accurate and clean.

The boxing of the JPM sideboard provides excellent rigidity and gives better impact resistance. And if there are significant impacts inside the tipper, deformation is limited: the interior wall may be marked without this being visible on the exterior.

The most robust welding technique on the market.

Over the last 10 years the JPM fleet in circulation represents 50,000 steel bodies.

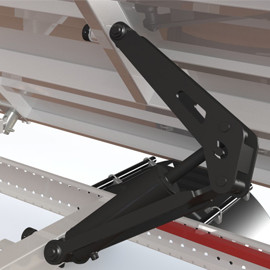

Tipping takes place on spherical roller bearings fitted with coded pins, avoiding any false manoeuvres.

The primer and the thermosetting resin-based epoxy powder paint make a very resistant 120 µm layer.

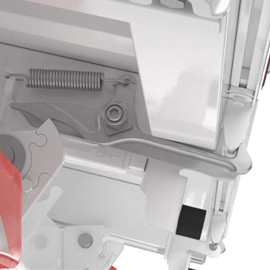

It is twice as fast for dumping as a telescopic cylinder and gives the three-way tipper great stability in the raised position. It is compact and there is no interference between the cylinder and the truck chassis.

The taper of the JPM pillar provides an efficient hold. The clamping screw makes it possible to take up any clearance which could appear over time. The pillar doesn't move and contributes to the long life of the tipper.

Double safety tall hinge

It offers optimal visibility due to its safety grille whilst allowing the addition of options and coupling possibilities.

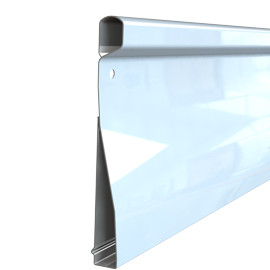

When closing the lip settles onto the platform thus ensuring better containment of fine loads such as sand.

The door unhooks when the tipper is at 15°. Unhooking takes place by a direct connection of the tipper with the hook (no chain, or cable or tie rod).

The JPM outer frame is fitted with a return which is a good means of lashing along the entire length of the tipper.

The profile of the JPM sideboard offers a very large surface for stickers while guaranteeing maximum visibility of visuals due to its smooth appearance.

Customise your JPM tipper very simply: order options via our store and fit them easily and quickly. In this way you have a tipper customised to your professional requirements. In spite of everything, this same tipper can evolve. It can be customised in a different way at any time.

Collision or an unfortunate impact with a bucket can happen quickly on a site. Carry out repairs yourself in record time: order your door or your sideboards with just a few clicks on the JPM website.

2 years’ guarantee on purchase of the tipper

+ 1 additional year free when registering the tipper guarantee on our website

+ 2 additional years on sale on our website

BODYWORK |

|

Tipper platform in galvanised steel sheet HX500, thickness 3 mm |

SUBFRAME |

|

• S355 steel tipper, thickness 4 mm |

SAFETY |

|

• Safety solenoid valve on cylinder |

FINISH |

|

• Galvanised elements: Steel sheet + 10 µm galvanisation + Shot blasting + 60 µm powder primer + 60 µm powder paint |