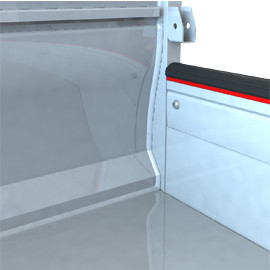

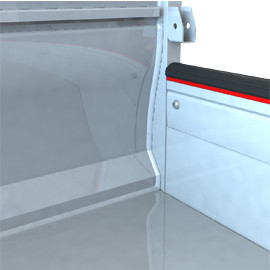

ROBUST FRONT FACE

The front face is welded to the dropside.

The front face is welded to the dropside.

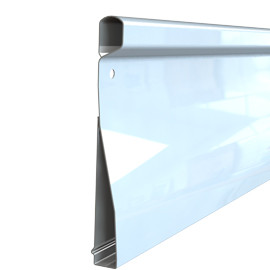

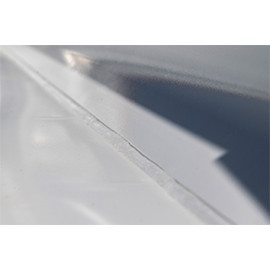

The boxing of the JPM sideboard provides excellent rigidity and gives better impact resistance. And if there are significant impacts inside the tipper, deformation is limited: the interior wall may be marked without this being visible on the exterior.

The most robust welding technique on the market.

Over the last 10 years the JPM fleet in circulation represents 50,000 steel bodies.

The primer and the thermosetting resin-based epoxy powder paint make a very resistant 120 µm layer.

It offers optimal visibility due to its safety grille whilst allowing the addition of options and coupling possibilities.

When closing the lip settles onto the platform thus ensuring better containment of fine loads such as sand.

All JPM tippers are fitted with stops on which the sideboards and the door rest when they are open.

The JPM outer frame is fitted with a return which is a good means of lashing along the entire length of the tipper.

The profile of the JPM sideboard offers a very large surface for stickers while guaranteeing maximum visibility of visuals due to its smooth appearance.

Customise your JPM tipper very simply: order options via our store and fit them easily and quickly. In this way you have a tipper customised to your professional requirements. In spite of everything, this same tipper can evolve. It can be customised in a different way at any time.

Collision or an unfortunate impact with a bucket can happen quickly on a site. Carry out repairs yourself in record time: order your door or your sideboards with just a few clicks on the JPM website.

2 years’ guarantee on purchase of the tipper

+ 1 additional year free when registering the tipper guarantee on our website

+ 2 additional years on sale on our website

BODYWORK |

| Platform bottom in steel S355 sheet thickness 3 mm |

| U-shaped side members in steel S355 thickness 4 mm and transverse spacers |

| Sideboards in steel S355, height 350 mm, thickness 2 mm, fold-down, removable, interchangeable (right/left, steel/aluminium) |

| Sideboard lifting aid from length 4060 mm |

| Integrated closing of sideboards |

| Front face steel S355, height 450 mm, thickness 2 mm |

| Cab protection in galvanised steel, grille (section 4 mm), removable |

| Rear door in steel S355, height 350 mm |

| Rubber opening stops on sideboards and rear door |

| Rear pillars in galvanised steel, thickness 3mm, removable, with 12 mm fixing bolt and straight fitting |

| HDPE (High Density Polyethylene) wraparound mudguards with raw aluminium support |

| Authorised aluminium side protections black powder paint |

| Geomet treated bolts (5 times more resistant than standard galvanising) |

| Outer frame adapted to lashing |

| Seals between elements that are not continuously welded |

FINISH |

| DKP sheet + Phosphating degreasing + Shot blasting + 60 µm epoxy powder primer + 60 µm powder paint |